Description

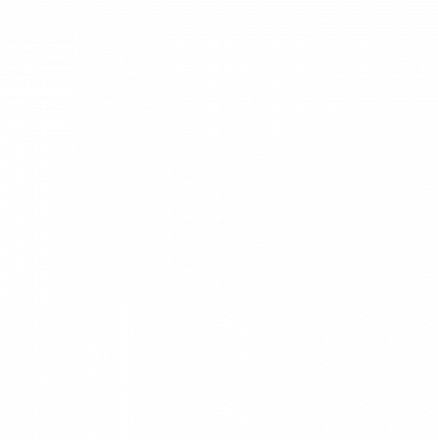

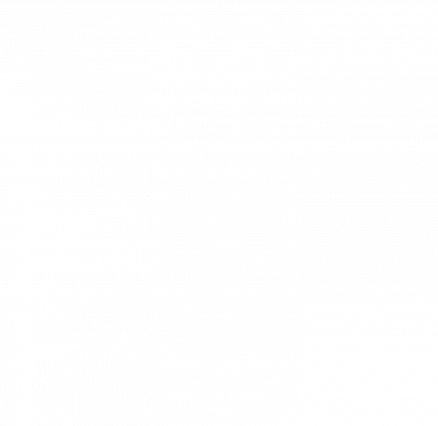

The updated M110P electric benchtop homogenizer, with modern touch screen interface, is a premium laboratory model. Powered by a standard 20-amp single-phase electrical outlet, the M110P requires no compressed air and no hydraulic cooling water to achieve up to 2000 bar (30,000 psi) operating pressure.

Using Microfluidizer® fixed-geometry interaction chamber technology and a ceramic (Zirconia) plunger, the M110P is capable of processing a wide variety of fluids, including oil-in-water emulsions, solids-in-liquid suspensions and cell disruptions — of even the most difficult yeasts and plant cells — in as few as one or two passes. This lab-scale homogenizer delivers a repeatable process that is guaranteed to scale up to pilot and/or production volumes.

Technical Specifications:

| Description |

M-110P

|

M-110PS

|

M-110P-20

|

M-110P-20S

|

| Pressure Range |

138 – 2,068 bar

(2,000 – 30,000 psi) |

138 – 2,068 bar (2,000 – 30,000 psi) |

138 – 1,379 bar (2,000 – 20,000 psi) |

138 – 1,379 bar (2,000 – 20,000 psi) |

| Minimum Sample Size | 50 ml | 25 ml | 50 ml | 25 ml |

| Flow Rate* Approximately (on water) |

up to 125 ml/min – 60 Hz

up to 105 ml/min – 50 Hz |

|||

| Product Temperature Limit |

73ºC (165ºF)

|

|||

| Power Requirements |

60 Hz/120 VAC/20 amp

60 Hz/230VAC/10 amp 50 Hz/220 VAC/12 amp |

|||

| Dimensions (W x D x H) | 85.8cm x 59.1cm x 52.7cm (33.75″ x 23.25″ x 20.75″) | |||

| Weight |

110 kg (242 lbs)

|

|||

| *Based on large chamber. Standard chambers will reduce flow rate. | ||||

Interested in the M-110P Microfluidizer® Processor? Request a quote or call us on +44(0)1954 232 776 to discuss your requirements.